Read the latest information on

Foot-and-mouth disease

Whenever crops are sprayed to control pests or weeds there’s a risk that the spray may affect crops other than the target. It’s recently been estimated that 20 per cent of the cotton crop in NSW and Queensland last year suffered from sprays intended for other crops.

Whenever crops are sprayed to control pests or weeds there’s a risk that the spray may affect crops other than the target. It’s recently been estimated that 20 per cent of the cotton crop in NSW and Queensland last year suffered from sprays intended for other crops.

The reason why so much off-target damage occurred this year is not yet established. Equipment can make a difference to the amount of spray drift – for example the choice of nozzle and rate of application – and weather conditions can also play a part.

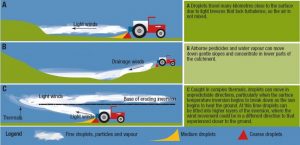

The fate of chemicals applied as sprays is determined by factors such as wind speed and direction, temperature and humidity and atmospheric stability.

Nick Woods, Program Manager at Plant Health Australia, says that weather conditions can cause dispersal of spray upwards into the atmosphere or, alternatively, concentrate off-target deposition at ground level.

“Spraying when it is very windy can clearly cause problems with spray drift. But another is when there is a surface temperature inversion layer, often when there is no wind present,” said Nick.

“But it can be difficult to judge when an inversion layer is present,” he added.

If the sky is clear at night, the ground can lose heat rapidly. Air close to the ground becomes cooler than air above.

“Since this is opposite to the normal condition, it’s called a temperature inversion.”

Spraying should be avoided under these conditions since small droplets are capable of remaining airborne for some time (under inversion conditions) and can cause severe damage several kilometres away from the sprayed area.

“Choosing the right time to spray and when not to spray to avoid damaging your own or neighbours’ crop takes some thought,” advised Nick.

“In terms of wind, it’s best to spray when there is a light breeze between about 3 and 15 km/hour, blowing away from susceptible areas. It also helps to know your property and where drift is most likely to occur.”

“If you know where cold air flows in winter, such as in a valley, or where fog may form or settle during the night, this is likely to be an area affected by spray drift when there is an inversion layer.”

A number of techniques are available to reduce the downwind impact of spray drift such as establishing buffer zones, using the right nozzle, release height and spray pressure.

“It’s worth doing a refresher course for appropriate methods to make sure you are not wasting money on unnecessary spraying and to limit spray drift,” said Nick.

Chemcert offers training courses in spray drift management. Some industries also provide training to their members. Check with your industry to see what’s available in your area.

Possible movement of airborne droplets in surface temperature inversion conditions. Source: GRDC

The first section of the booklet Spray drift management: principles, strategies and supporting information

provides a basic guide on spray management. (CSIRO Publishing)

Surface temperature inversions and spraying: The influence of surface temperature inversions on spray operations (GRDC fact sheet)